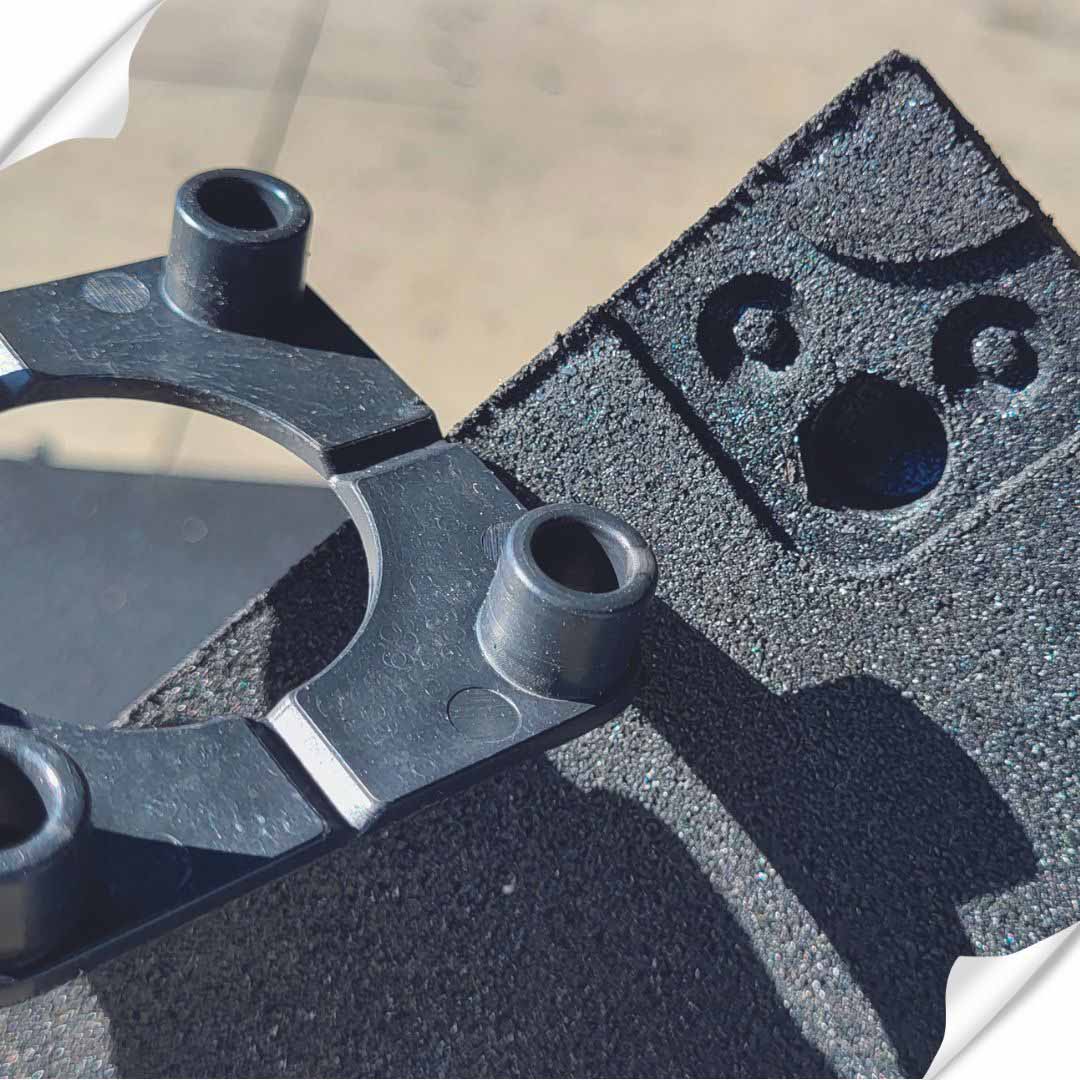

ECO-GYM TOP LOCK

Anti-trauma flooring for Gyms and Fitness Areas with mechanical fastening system

ECO-GYM TOP LOCK is the perfect solution for those looking for professional, sturdy and easy-to-install flooring in sports environments, gyms and fitness areas. Thanks to the practical interlocking system, installation is quick, without the need for adhesives, and guarantees high performance in terms of strength and comfort.

Features

This flooring stands out for its ease of installation and remarkable shock absorption properties. In the following section you will discover all the advantages and special features that make ECO-GYM TOP LOCK an ideal choice for gyms, fitness centers and sports areas.

Interlocking system: the “TOP LOCK” system allows easy and stable assembly, minimizing installation time.

Flexibility and durability: special recycled rubber composition absorbs shock and resists wear and tear, ideal for intense training and professional use.

Non-slip surface: surface finish provides adhesion preventing injury.

Sound insulation: the structure of the material reduces the propagation of noise, providing a quieter and more comfortable environment.

Ease of cleaning: ECO-GYM TOP LOCK flooring is easy to clean and resists major cleaning products.

Technical Specifications

ECO-GYM TOP LOCK is made with quality and performance over time in mind. Below you will find the technical specifications that testify to the reliability of this heavy-duty floor.

| THICKNESS (mm) | 20 | 30 | 40 | 50 |

| format 1000×1000 | × | × | × | × |

Colors

ECO-GYM TOP LOCK is available in black.

BLACK

Applications

Gyms and fitness centers: durable, non-slip flooring for weight rooms, cross-training areas, functional training and cardio areas.

Functional training box: great for absorbing impact and reducing noise when using heavy equipment.

Multipurpose sports facilities: suitable for sports halls, school centers and sports associations.

Home areas: for those who want to set up a fitness area at home without sacrificing quality and safety.

Benefits

Laying Guide

The installation of recycled rubber anti-trauma flooring can be safely performed even by people who have never done this type of work before. In most cases, laying is done by simply placing the plates on the original flooring. However, it is necessary to comply with a set of procedures to ensure proper placement of the flooring. If in doubt, qualified personnel can always be called in for the installation, a solution that guarantees the result is “workmanlike!”

The following are the main points to be observed when laying tile flooring:

- Checking the existing pavement: First of all, we need to make sure that the existing pavement has no depressions or imperfections whatsoever. Proper installation involves an even subgrade.

- Site preparation: The area where the pavement will be laid must be prepared. This includes thorough cleaning of the existing pavement; all traces of dirt and debris must be removed.

- Laying the plates: We start laying the plates starting from the center of the room or the side we want to use as a guide. Preparing a draft of the laying pattern can be helpful in reducing waste and optimizing the scenic effect.

- Finishes and safety checks: After installation, it is important to check for unsealed protrusions or edges that could pose a safety hazard.

Cut

Should it be necessary to adapt the flooring to irregular spaces or trim edges, cutting can be done with: Professional cutter.

Before making the cut, we recommend precisely drawing the guide lines using a ruler or a square, so as to achieve clean, smudge-free edges.